AQAFORCE Electric Boat Powertrains

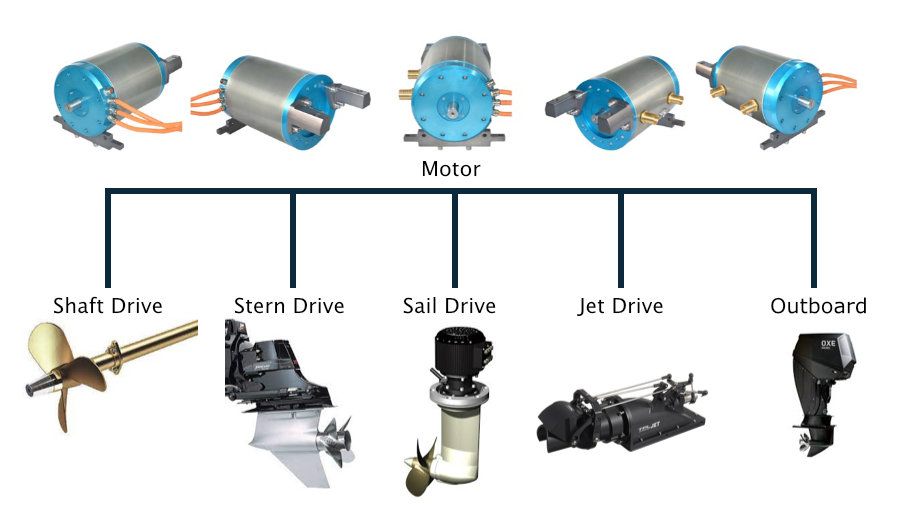

Electric boat motors as inboards for sterndrives, shaft systems, jet drives and outboards.

High-voltage drive technology

AQAFORCE - your specialist for smart electric powertrains and hybrid drive systems.

We exclusively design highly efficient drive systems using proven industrial components and employing our own developments that have been tested in practice.

When designing drive systems, AQAFORCE consistently pursues an integral approach. Everything comes from a single source and is matched to the system (motor, battery, charger and control system).

Of course, we take into account the geometry of the vessel, the specific application requirements and the expectations of our customers when designing the system. The result is the perfectly matched AQAFORCE propulsion system.

The current power class ranges from 20 kW to 400 kW engine power.

Drive combinations with shaft units, sterndrives, jet turbines and in outboards are possible.

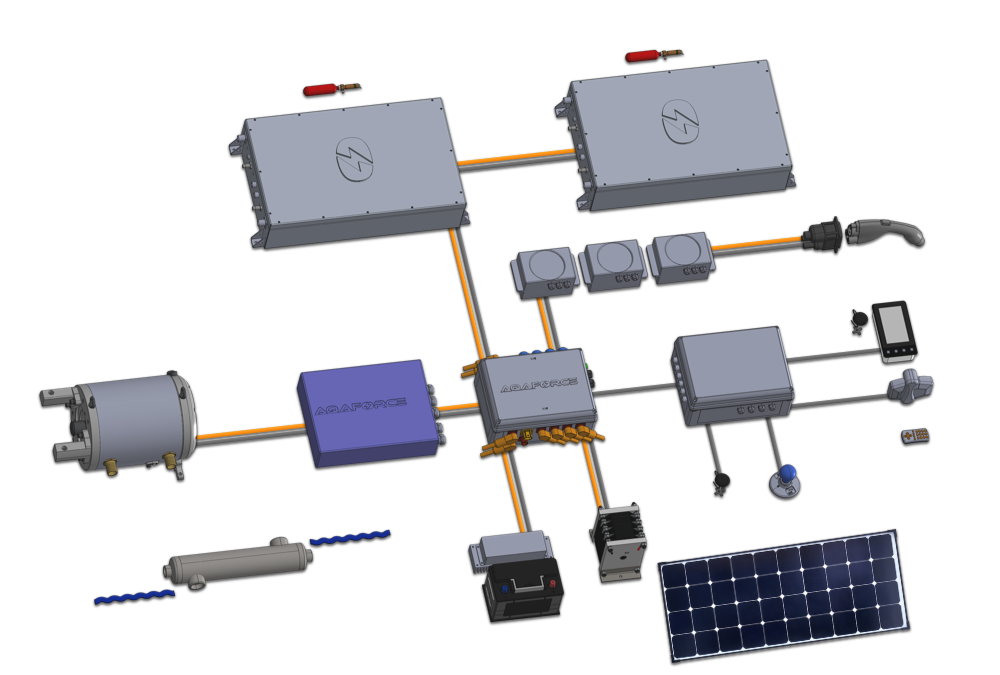

System overview Single-Drive

- in-house development by AQAFORCE

- 10 times better heat dissipation due to the special star design

- 4 times higher coolant flow (min. 40 liters per minute) due to larger cooling channels than usual on the market

- latest generation of synchronous motors

- efficiency 96%

- electronically commutated permanent magnet motors

- seawater cooling via primary circuit

- seawater resistant aluminum

- integrated AQAFORCE thrust bearing to absorb the thrust of the propeller - no additional thrust bearing required

- multi-purpose mounting device

- protective anodes

- IP67 protection class

- protection class IP 67

- remote monitoring via telemetry

AQAFORCE has set its own battery standards.

Modular battery bank concept (seriell up to 4 / parallel unlimited):

- automotive standard NMC cells highest quality and safety standards

- energy density: 169 Wh/kg, 2.3 C

- lifetime: up to 9 years, at 80% DOD, 25° ambient temperature more than 3500 cycles

- robust & safe aluminum housing from own production

- IP67 protection class

- integrated sensor controlled NOVEC gas fire extinguishing system (no powder)

- rated voltage: 175 V

- capacity: 20,25 kWh

- weight: 120 kg

- dimensions (LxWxH): 830 x 469 x 337 mm

- internal cooling via secondary circuit

- redundant data logging / monitoring: overvoltage / undervoltage, smoke / heat, humidity / gas

- compliance with relevant norms and standards (CE I UN38.3 I DNV GL coming soon)

Node of the overall system: bundles electrical and digital lines and cables, waterproof according to protection class IP67.

- insulation monitoring

- charging monitoring

Steering control unit, networked display, throttle, remote control, antennas as well as Smart Boat Access Point. Waterproof according to IP67 protection class.

- integration remote control

- wireless connectivity, LTE router via cellular / WLAN

- CAN-Bus

- NMEA 2000

- 7" color touch display

- 4 illuminated stainless steel push buttons

- start button, key-free

- manually dimmable night mode

- integrated CAN-Bus

- output for trim & tilt by AQAFORCE control unit

- top mount

- side mount

Integration of electronic on-board remote monitoring and operating systems, such as camera, navigation, lighting.

Interface for

- fuel cell methanol

- fuel cell H2

- generator Diesel DC

- photovoltaic modules

Allows remote control of the system on board.

On-board shore power chargers for charging the system in port.

Seawater heat exchanger made of composite material

- corrosion-free titanium spiral

- low internal resistance up to 120 liters per minute

- noiseless active pump for primary and secondary circuit

- maintenance-free

AGM battery for system startup

DC/DC converter: connects the boat's 12 V DC electrical system to the battery system and charges the 12 V battery.

Motor System Combinations

FAQ

In principle, yes - but it should make sustainable sense. Our goal is to deliver a very reliable, affordable and fully integrated system, so we listen to our customers and always determine the specific requirements first, such as charging time, range, speed and investment volume.

After that, the modular design of the AQAFORCE drive system (20 - 400 kW) can show its strengths and from a variety of motors, batteries and chargers, a drive system perfectly adapted to the project is then configured.

A system that comes from one source from A to Z is user-friendly and also clear in service matters - there is only one contact person here and that is us, the developers.

According to our understanding, a boat with an AQAFORCE-Ssystem is not only as safe as a combustion engine, but even much safer:

- optimal theft protection by electronic lock

- highest redundant safety standard on battery and system level

- the monitoring system continuously evaluates data: optimal voltage / smoke / temperature / humidity and gas

- each battery box is additionally monitored by a sensor-controlled Novac fire extinguisher

- handling is easier - power can be dosed more precisely

- remote controls allow maneuvering the boat for example from the bow or stern of the boat

- no fire risk due to refueling

- no interference from diesel fumes or gases

We do not leave you alone.

AQAFORCE has a particularly high standard here - we not only supply all components from a single source, but also service directly and without detours.

We can be reached by telephone 24/7 if necessary - here you are not talking to a hotline, here you are talking to the developer of AQAFORCE.

All error messages that appear on the display are not cryptic, but formulated as plain text information, so that the error pattern is always clearly described.

More importantly, however, the smart design of the AQAFORCE system allows us to provide active assistance anywhere in the world.

Remote monitoring allows us - with your permission - to dial into your system worldwide via Sim Card and correct any errors or install new software updates. For mechanical assistance, we currently have two service centers in Germany and Austria.

Lithium-ion batteries are subject to an aging process that is unavoidable for many technological products. Safety and longevity are particularly important to us, which is why we only use battery cells for our AQAFORCE batteries that come from the automotive industry and are equipped with an intelligent battery management system (BMS). As a result, up to 3,500 charging cycles (SOC 80%) are achieved. In addition, extremely high or low outside temperatures can contribute to a slight decrease in capacity.

However, when applied to the service life of a private user, concerns are misplaced; here, the battery bank will still have at least 80% of its original capacity after 9 years of proper use.

The charging time is significantly influenced by four factors:

- size of the battery bank in kWh

- power of the chargers in kW

- how fully the batteries should be charged

- capacity of the charging infrastructure

The standard battery at AQAFORCE has a capacity of 20.25 kWh.

Standard charger configuration at AQAFORCE is 3 x 3 kW.

Preset capacity e.g.: 80% (to reach an optimal lifetime).

AQAFORCE's smart charging control system monitors the charging process, our mains voltage detection avoids load peaks and ensures a continuous charging process.

Example calculation:

A boat with a battery bank of 81 kWh (4 x 20.25 kWh) is charged with 9 kW.

80% (64.8 kWh) is reached after only 7.2 hours and 100% (81 kWh) is reached after 9 hours.

From spring 2022 there will also be a 22 kW charger which will drastically reduce the charging time.

Example calculation:

A boat with a battery bank of 81 kWh (4 x 20.25 kWh) is charged with 22 kW.

80% (64.8 kWh) is reached after only 2.95 hours and 100% (81 kWh) is reached after 3.68 hours.

However, the future is the DC charging. Provided the right infrastructure is in place, it will then be possible to charge up to 120 kW directly into the battery bank using the CCS plug. This corresponds to charging times of less than one hour.